OWP EYEWEAR CHALLENGE FOR THE INTERNATIONAL DESIGN CONTEST 2018

This was a 2-week project where I was tasked to design a pair of attractive & functional eyewear.

Glasses handcrafted from balsa wood & lenses sourced from an existing pair.

INVISIBLE ZINC POINT OF SALES DISPLAY

A point of sales display for Invisible Zincs' Sunscreen line that utilises vacuum forming as the main method of manufacture. The aim was to entice interest and engagement with the product, without detracting or upstaging it. The design is inspired by dunes and the natural textures of sand on beaches.

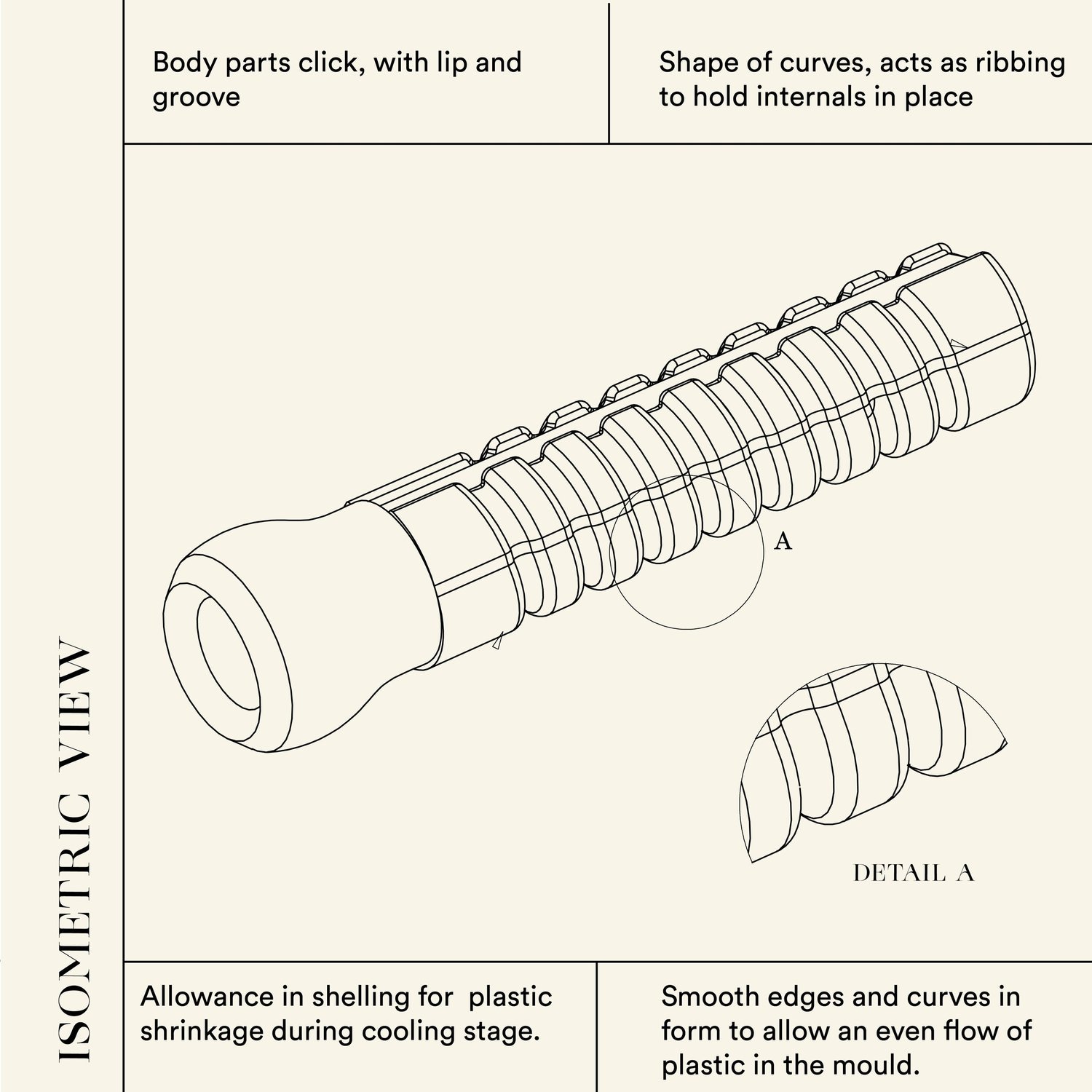

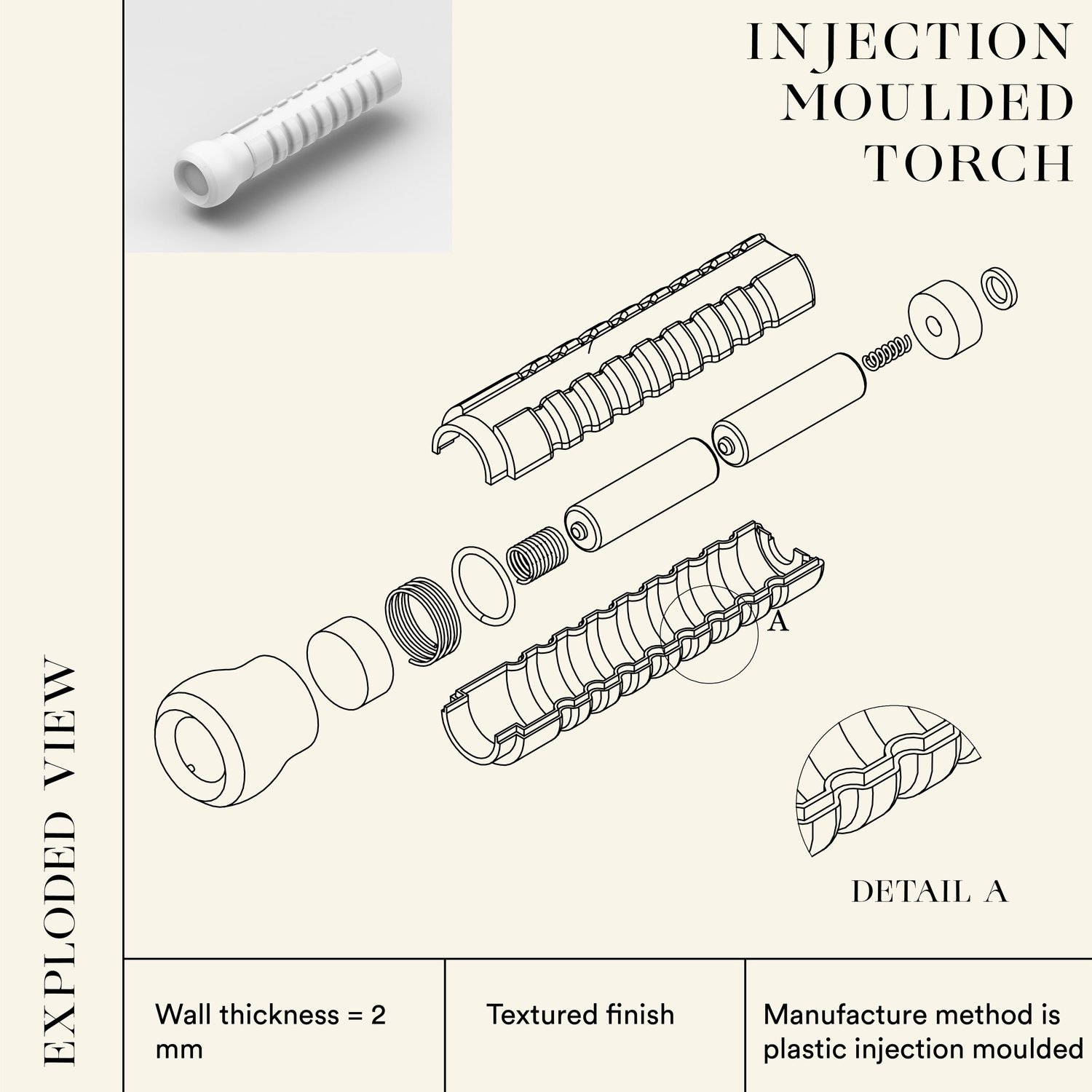

LACE TORCH - INJECTION MOULDING AND CRAFT

This project explores the manufacturing process of injection moulding in combination with hybrid design. Lace torch is a personalised product that brings together the digitally fabricated with the handcrafted art of weaving and tying knots.

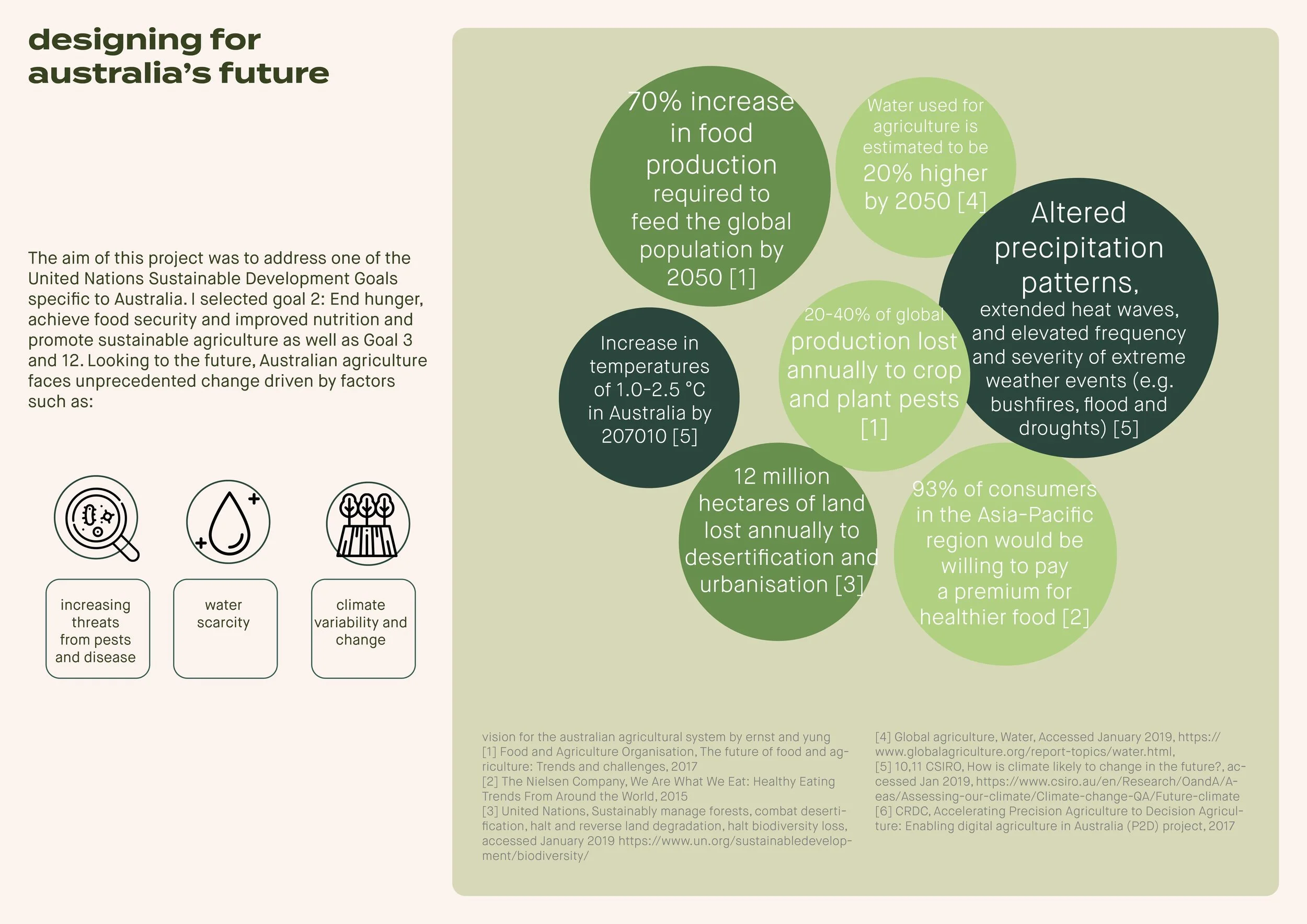

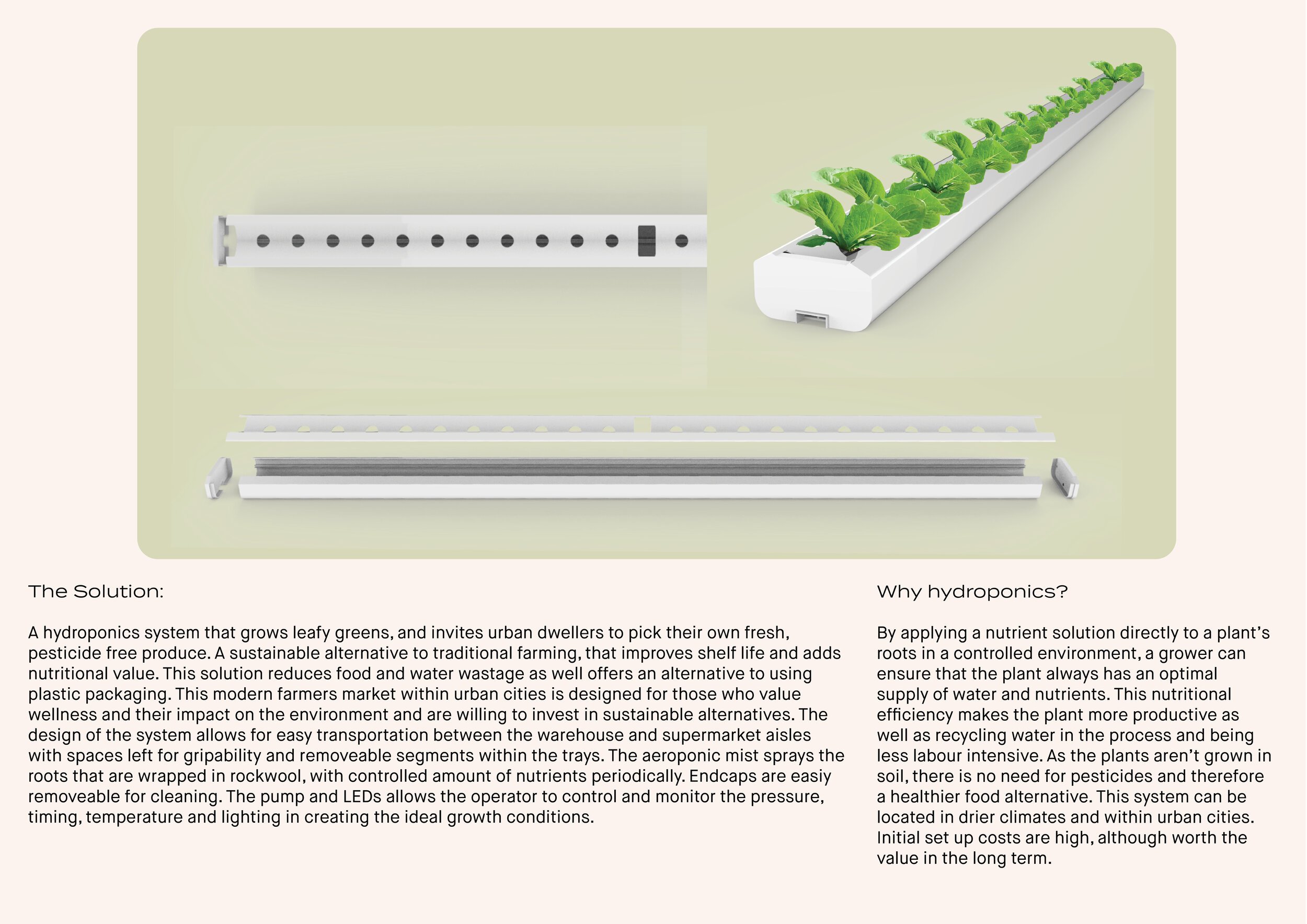

HYDRO BLOOM

Designing for Australia’s future by addressing the United Nations Sustainable Development Goals:

GOAL 2: End hunger, achieve food security and improved nutrition and promote sustainable agriculture

GOAL 3: Looking to the future, Australian agriculture faces unprecedented change driven by factors.

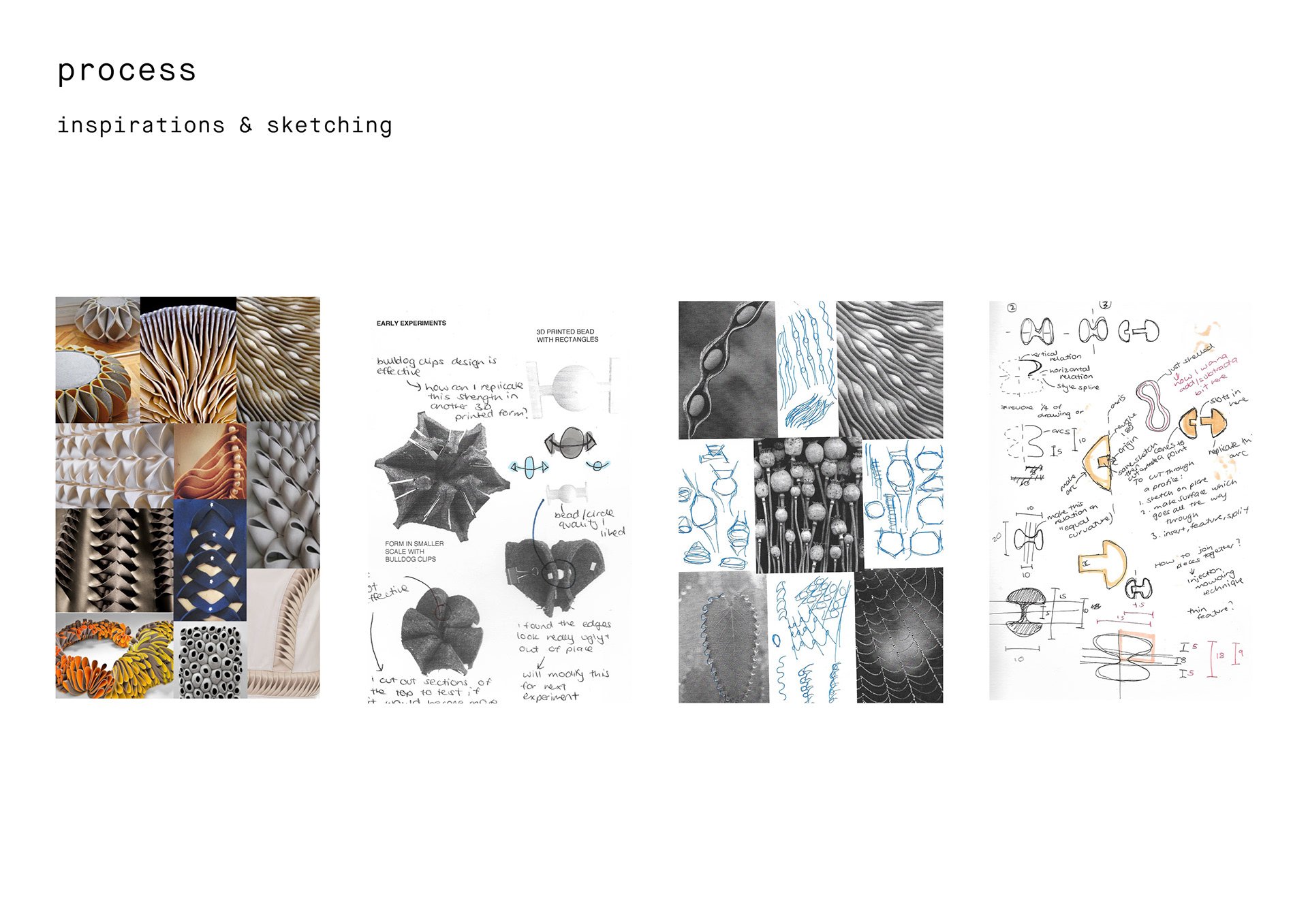

HYBRID

This project explores the concept of hybrid design, where elements of digital fabrication and the handcrafted meet. If one was removed, the object would no longer exist in the same way.

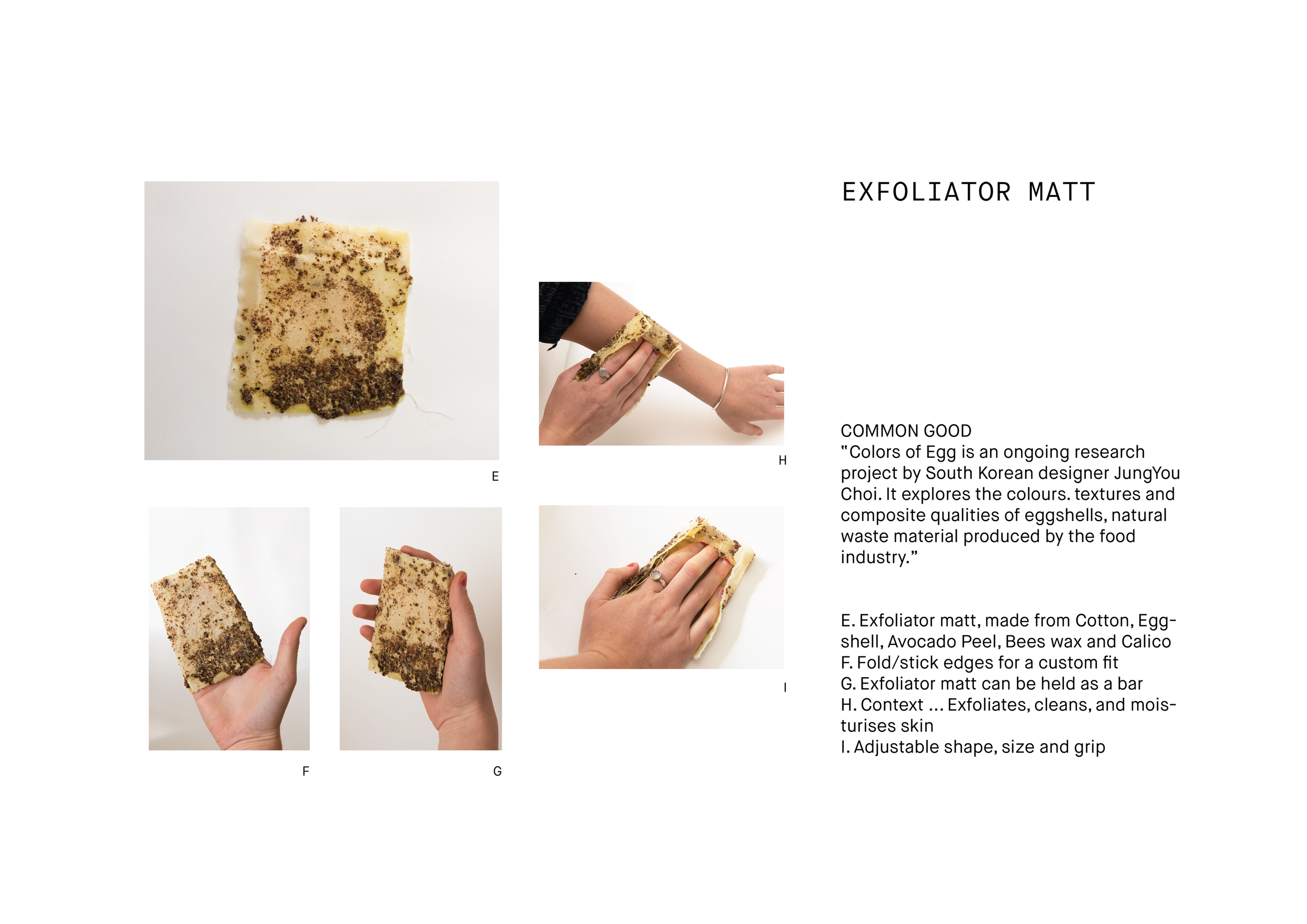

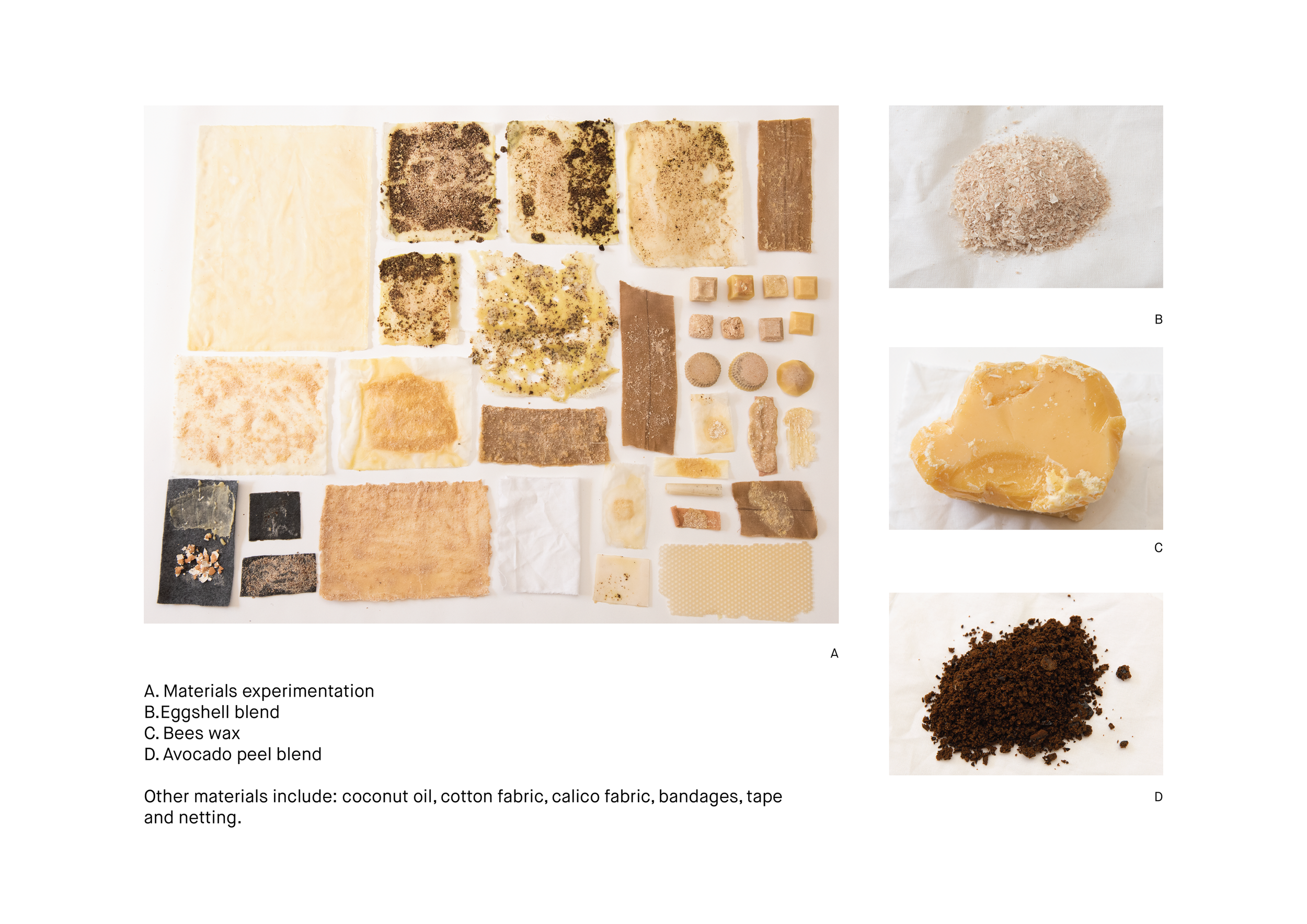

COMMON GOOD

Common Good was an exhibition at the Powerhouse Museum in 2018 addressing sustainability and change. Within the exhibition was a series of works that explored sustainable material alternatives.

The below project was inspired by JungYou Chois’ Colors of Egg series, in the Common Good Exhibition.

“It explores the colours, textures and composite qualities of eggshells, a natural waste material that is produced by the food industry. JungYou Choi has developed objects that combine eggshells in different densities and textures, including candle holders and soap, often colouring them with the outer skin of onions and avocados.”

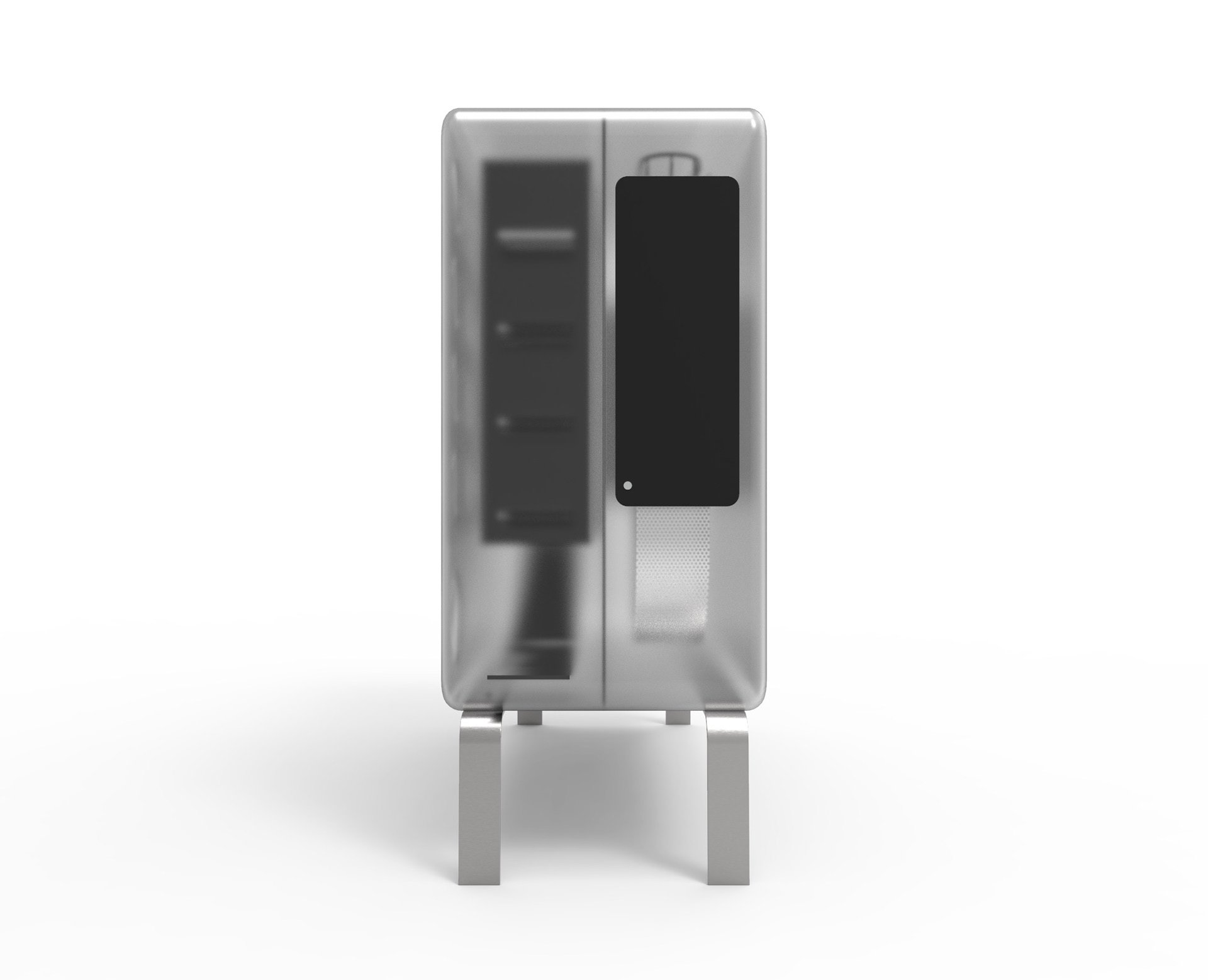

CIRCULAR ECONOMY TOWEL VENDING MACHINE

Value Proposition: Backpackers are on budgets and as a result buy or rent low quality, un-appealing towels whilst travelling. This towel vending machine offers convenience to the traveller by taking away the effort of having to carry, store and wash their own towels. It's a service that enables the sharing of products in order to reduce waste, as well as provide travellers with a high quality offering that enhances their experience and ease of use.

A high end luxury towel, weaved on an industrial loom. The towel is made from 50% Buldan cotton and 50% recycled cotton that is collected from factory offcuts and discarded towels.

The towel has a waterproof RFID chip, the size of a small circle, and is located in the top left corner. This chip allows the towel to be hung up when returned, and to register the user who has returned it.

The towel is 90 x 170mm in size.

RE-CONNECT EXHIBITION

Member of the UNSW Industrial design Honours Exhibition Committee

- Logo concept & design, outsourcing of animation

- Marketing content on @ides_unsw Instagram account

- Organising & collecting exhibition content & curation: poster design, write ups on students, video content

SPATULA

The spatula is a hand tool that has been around for a long time. This project presented an opportunity to explore and re-define the ergonomic design elements of the spatular that ultimately inform how we interact with it whilst cooking.

SHEET METAL

This project was based on understanding and expressing the essence of sheet metal as a material. The object designed had to be useful, and constructed using simple methods of manufacture such as folding, bending and rolling.

OX CONCRETE SCREED

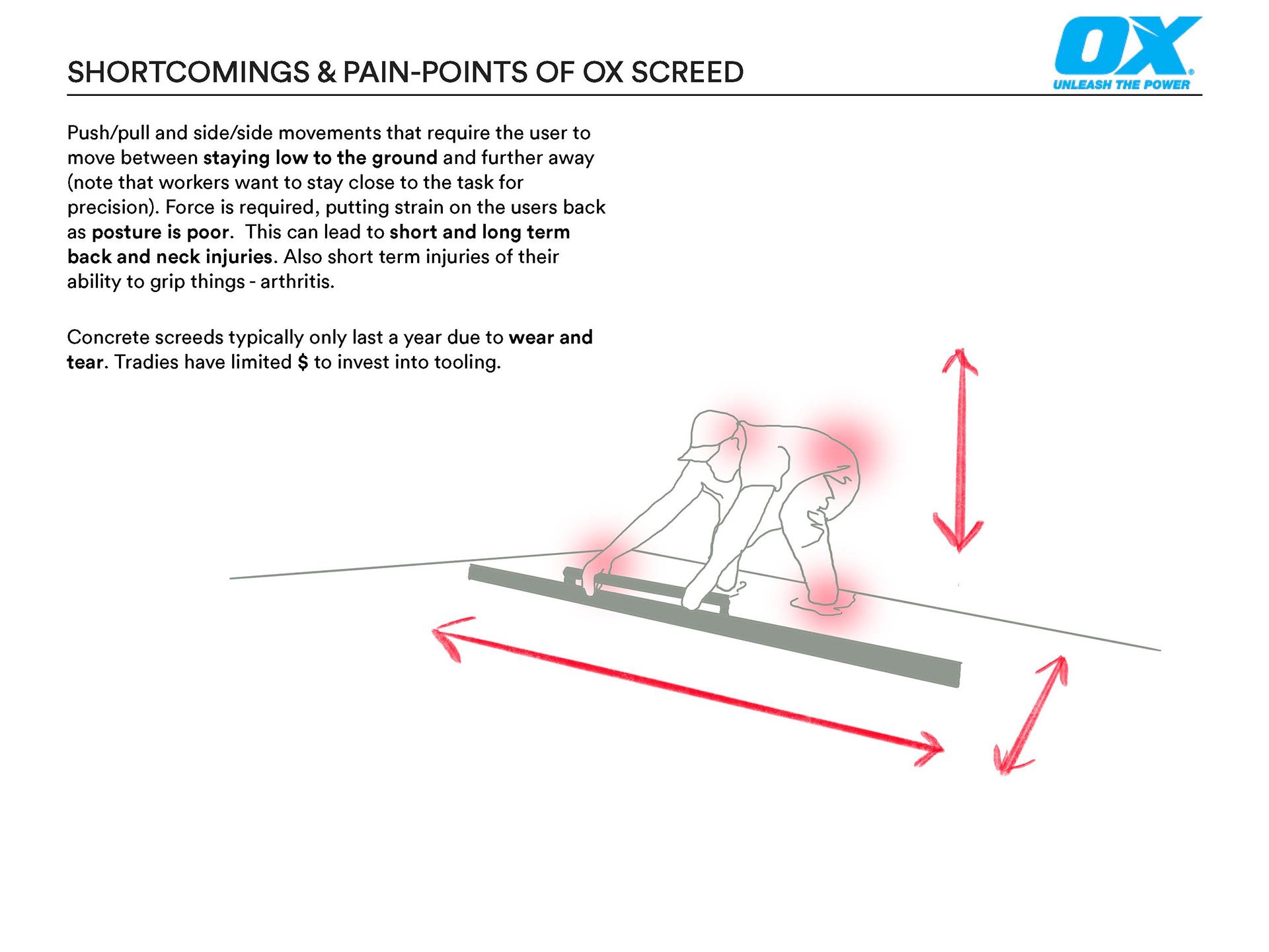

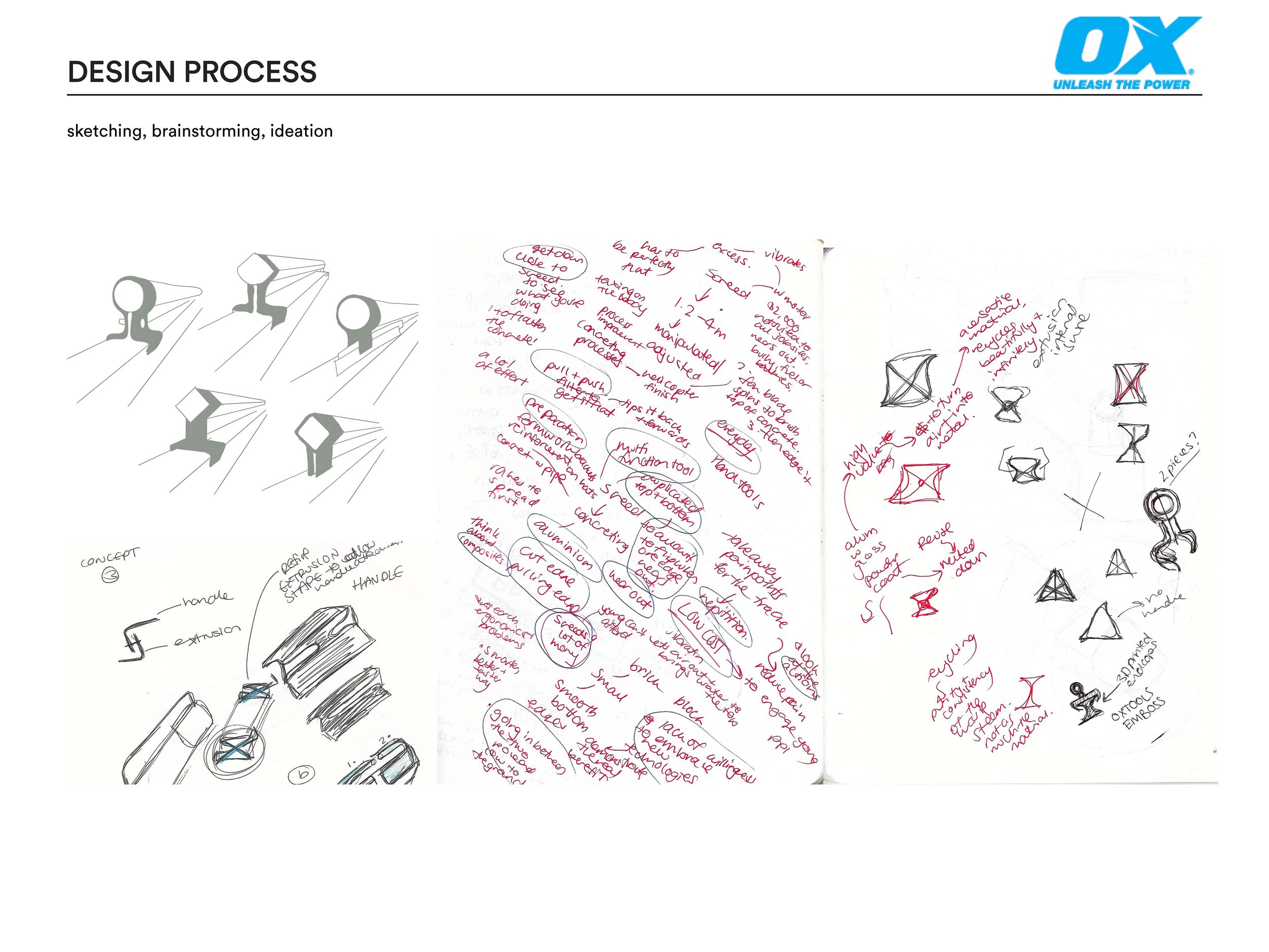

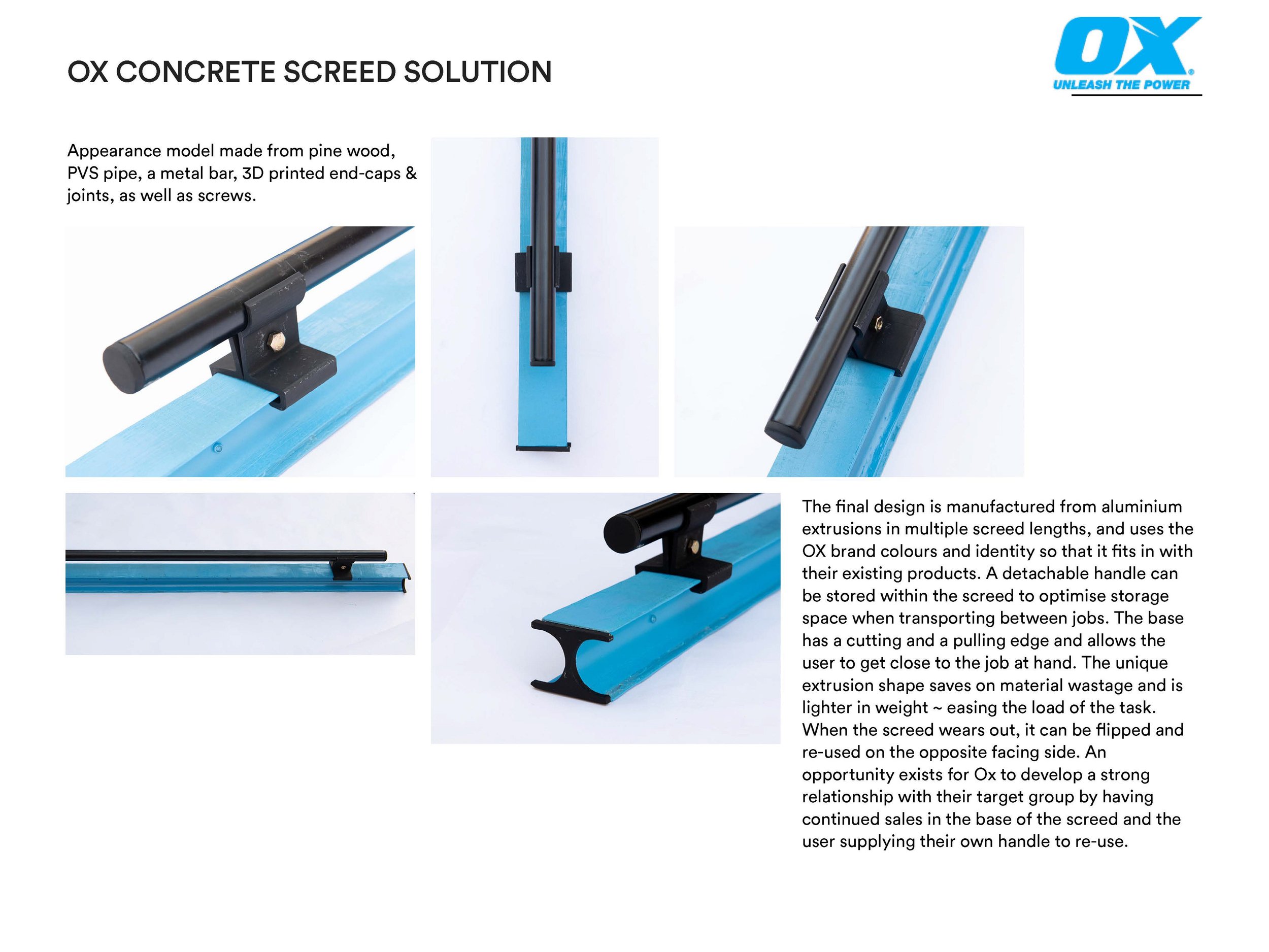

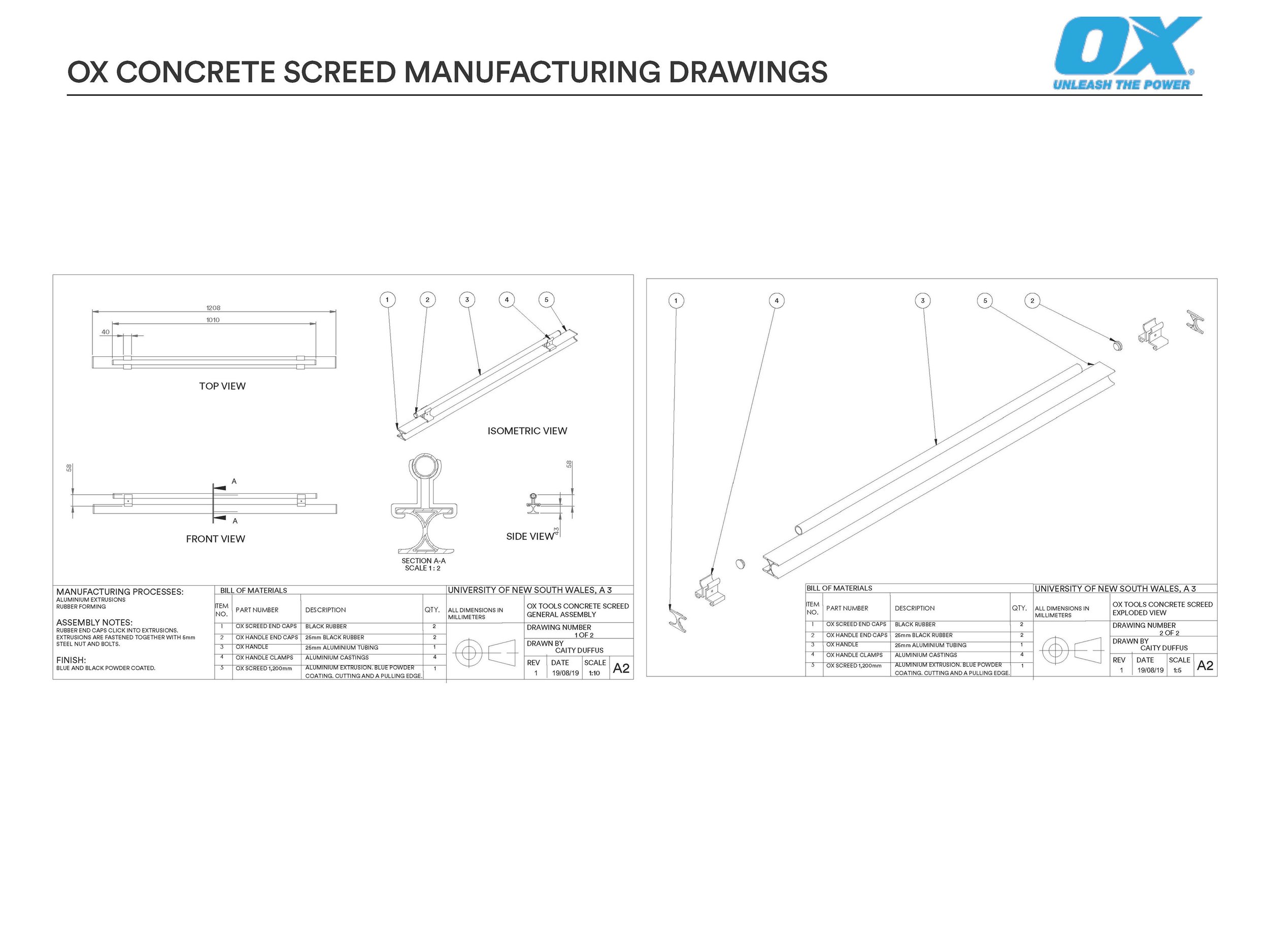

Resigning the OX Concrete Screed, addressing the shortcomings and pain points of existing designs.